High throughput screening for optimization of purification process – CDMO perspective

With the recent advances in biotechnology, there has been a considerable need for faster and more efficient development of biotherapeutics and their approval process. This translates to shorter process development timelines for both upstream and downstream operations. As CMOs it becomes very essential to develop a platform approach involving a high throughput screening technology for evaluating multiple conditions for process optimization considering scalability along with manufacturability. With the development of small-scale multi-parallel bioreactor systems leading to screening of several high performing cell lines with high throughput technique, it becomes increasingly necessary to also have a similar throughput system for downstream purification process. Thus to cater to these needs, high throughput process development has emerged as a predominant technique for downstream unit operations used by industry considering it to be cost efficient and also time saving methodology.

The high throughput process development technique for downstream unit operations are primarily used for chromatography stages which involves resin screening followed by optimization of process conditions (bind, wash and elution). At Kemwell we have optimized a high throughput screening (HTS) methodology which can be used for these purposes leading to significant decrease in process development timelines. The case study provided below focusses on optimization of high throughput method for resin screening.

CASE STUDY

Currently, increasingly high number of resins is available from different manufacturers and it is important to screen these resins for an optimum balance between binding efficiency and binding capacity to obtain maximum capacity utilization. This is more valuable for protein Aresins since these are used for capture stage in the platform mAb process train and also has high impact on the manufacturing cost. In this case study thermodynamic and kinetic effects of protein adsorption phenomenon for different protein Aresins are evaluated which are the indicators for binding efficiency and capacity respectively.

Six resins were screened for protein A chromatography stage using the HTS technique. Micro Bio-Spin columns from

BioRad were used which were packed with 10µl of resin per column. 400µl of protein solution at concentration of 0.5 to 2.5 mg/ml was added at different incubation times (5 to 120 mins) and the flow through was analysed for protein concentration.

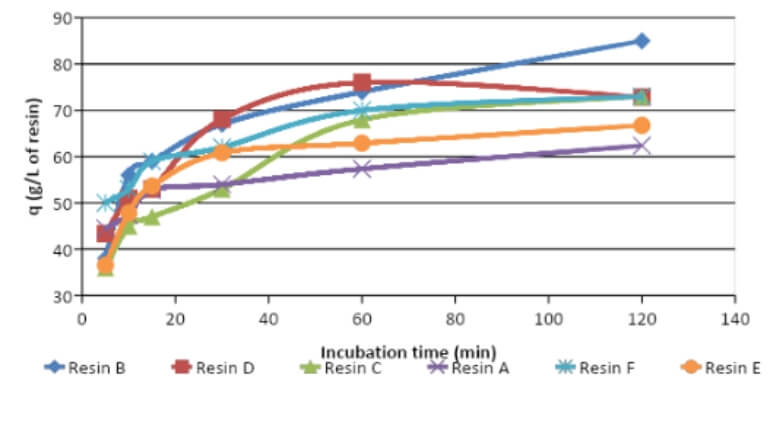

Kinetic effects were evaluated through kinetic uptake curves plotted between binding capacity and incubation times at different concentration of load (C0). Based on the kinetic uptake curves, the equilibrium stage or saturation capacity is attained for most of the resins at 120 mins of incubation time. A representative kinetic uptake curve at load concentration of 2.5 mg/ml is shown in Figure 1.

FIGURE 1 : KINETICS UPTAKE CURVES AT C0 OF 2.5 MG/ML

CONCLUSION

As observed from the above case study, high throughput methodology is a useful tool in screening different resins and can be employed for all chromatography stages. Moreover the outcome obtained from the high throughput screening studies can be also successfully extrapolated to higher scales or dynamic condition which is critical for further process finalization.

Apart from resin screening with respect to binding efficiency, the high throughput methodology can also be used for evaluating selectivity for impurity removal or control. Considering the increasing number of resins available for all the chromatographic stages from different vendors, this tool provides the feasibility for obtaining information on thermodynamics of the protein–resin interaction and also selectivity with respect to impurity removal for multiple resins within a short period

REFERENCES

1. High-throughput Process Development with PreDictor™ Plates Principles and Methods; GE healthcare

2. Jonathan L. Coffman, Jack F. Kramarczyk, Brian D. Kelley High-Throughput Screening of Chromatographic Separations: I. Method Development and Column Modeling; Biotechnology and Bioengineering, Vol. 100, No. 4, July 1, 2008

Categories

New at Kemwell

A collection of stories about our people, our capabilities, our research,

and the ever-changing face of our firm.

Business Wire release Milestone expands India’s role in global biologics manufacturing;…

Introduction: Recent advances in biologics development are primarily focussed on development…

Introduction: Size variants determination is a critical quality attribute for a…